Deming’s 14 Points are a set of management practices that can help improve your organization’s products, services, and processes over the long term. They are also a core component of implementing total quality management (TQM).

The 14 Points were proposed by Dr. William Edwards Deming (1900 – 1993), an American engineer, management consultant, and pioneer of the quality management movement.

To understand Deming’s 14 Points, you need to understand the concept of variation. From Deming’s perspective, variation is the scourge of business – the more variation (time delays, supply chain variations and delays, price variations, work practice variations between employees), the more waste, and therefore the more unnecessary costs being drained from the business.

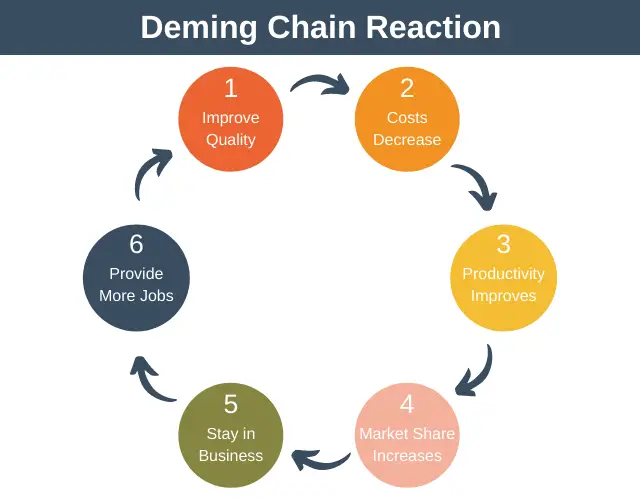

Deming’s 14 Points can help you build quality into every level of your organization. Implementing the points can enable your business to prosper, not by cost-cutting but by a process of continuous improvement. Over time, by implementing the points, Deming says that you can create a virtuous chain reaction.

The chain reaction begins when you use Deming’s 14 Points to improve the quality of what you do. Improved quality, in turn, decreases your costs because you need to do less rework, you make fewer mistakes, you have fewer delays, and you make better use of your machines and materials.

With less time wasted, your organization’s productivity will improve. Better productivity also results in a lower cost base. If you pass some of these cost savings on to your customers and combine that with the improved quality of your products, you’ll start to capture more market share.

This will enable you to not only stay in business but also to provide more jobs and thrive.

Note that Deming’s 14 Points are not a checklist whereby you aim to tick everything off. Instead, you can pick and choose which points you want to implement.

Deming’s 14 Points with Examples

Let’s jump in and look at each of Deming’s 14 Points with examples.

1. Create Constancy of Purpose

Constancy of purpose is about prioritizing continuous improvement over the long term. Improvement isn’t just something you should do ad-hoc when it suits you; it should be core to everything you do and one of your highest priorities.

Doing what you’re doing now only better is all well and good, but constancy of purpose is about committing to allocate resources to long-term planning, research and development, and improving the design of your product or service.

Increasing customer satisfaction, developing employees, reducing errors and waste should be continuous and expected of all employees.

Example:

Here are some examples of how to implement this constancy of purpose:

- Commit to developing your team on an ongoing basis.

- Create a vision of the future. Make sure every employee knows this vision.

- Ask for process improvements and product quality improvements every week from your team.

2. Adopt the New Philosophy

Adopting the new philosophy is about striving for perfect quality. You must no longer tolerate commonly accepted levels of mistakes, people who don’t know what they’re doing, defects, and inadequate supervision.

At the heart of this new philosophy should be the desire to put your customer’s needs first.

Example:

Here are some examples where you could adopt the new philosophy.

- If you run a business delivering white goods, is the commonly accepted four-hour delivery window really putting your customer’s needs first?

- If you run a restaurant, is it acceptable for a customer to order only to be later told that what they ordered is out of stock?

- Is it acceptable to wait over fifteen minutes to speak to a customer support team member if you run a bank?

3. Stop Depending on Inspections

Stop depending on inspections to improve quality and build quality into your processes instead. An inspection doesn’t improve quality because it happens too late. At the point of inspection, the quality of the product already exists, good or bad, so all an inspection does is find an existing lack of quality.

Toyota makes exceptionally reliable cars, and it has achieved this by building quality into its processes. This approach doesn’t just apply to manufacturing. A manager “signing-off” a team member’s work doesn’t improve the quality of that work either.

Example:

Imagine you run an e-commerce store. The next time you identify a problem, then in addition to fixing the issue, examine the process that enabled the problem to happen, and come up with a way to error-proof the process.

If you can error-proof your process, you remove the need for inspections, and the quality of your products will improve over time. You may wish to combine this with statistical control methods to show that your processes improvements are having the desired effect.

4. Focus on Total Cost, Not Price Tag

Many companies purchase goods and services based solely on price alone. Similarly, many organizations will source identical items from different suppliers and pit those suppliers against each other to drive down the price.

While this might work in the short term, Deming believes it’s a poor long-term strategy. Deming encourages you to use a single supplier for any one item and build a long-term relationship with that supplier, where you consider them an extension of your own business. Doing this will eliminate many of the hidden costs that occur when you purchase items based solely on price.

Example:

Imagine you are a watch manufacturer. Right now, you purchase an identical part from six different manufacturers. Let’s examine the hidden benefits you could achieve by transitioning to a single supplier:

- You’d have a smaller supplier base to manage.

- There would be no variation in quality between suppliers.

- You could maintain a smaller inventory because your supply chain is more straightforward.

5 . Improve Constantly and Forever

Continuous improvement isn’t something you should do when it’s convenient. You should commit to continuous improvement always and forever.

Instead of reacting when something goes wrong, invest in continuous improvement to consistently improve the quality of your products and processes.

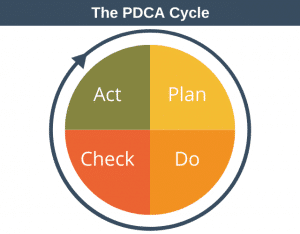

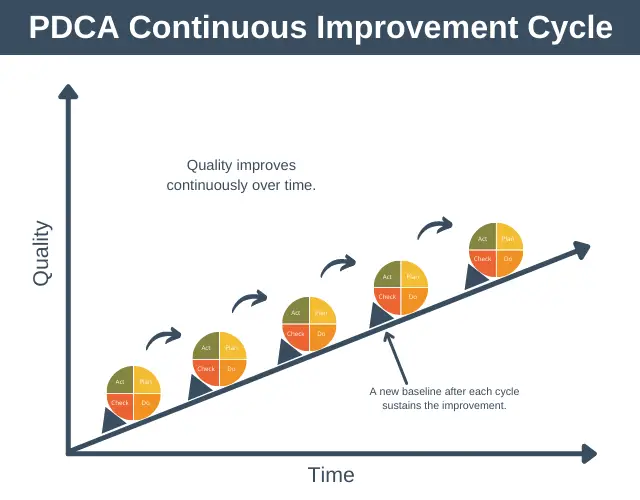

Deming created the PDCA Cycle to help organizations continuously improve. If you use this cycle, then over time, your product quality will improve, your customer satisfaction will increase, your costs will reduce, and ultimately your business will grow.

Example:

Imagine you are a senior manager at a sizeable online technology company. Firefighting and reacting to problems as they arise is not continuous improvement; it’s just rectifying something to get it back to where it should have been in the first place. You decide to invest in PDCA and every week make improvements to your products and processes, such as:

- Improve how you select your suppliers.

- Improve the process for hiring staff.

- Improve your software development process.

- Improve the onboarding training for new team members.

6. Institute On The Job Training

Without adequate training, you are wasting the abilities of your employees. Not only that, you are holding them back from taking more pride in their work. People can do amazing things if given the opportunity.

Train people for consistency to help reduce variation. This training needs to encourage people to understand the big picture and why it is vital to continuously improve processes. Provide an environment where staff learn from each other. Move away from a blame culture to one where people work together to improve quality.

Example:

Imagine you run a small startup with twenty employees. What happens when you hire employee number twenty-one? Right now, you introduce them to the team and expect them to be up and running immediately.

Wouldn’t it be better if:

- You established clear job responsibilities.

- You defined what good quality work looks like.

- You had a standard process they could follow.

- You provided them with complete onboarding training.

7. Institute Leadership

Institute leadership is one of the most controversial of Deming’s 14 Points as it is the opposite of what most managers do today. Most managers today look for their employees to hit targets, react to problems as they happen, and then hold them accountable when things go wrong. Their idea of continuous improvement is simply to set higher targets each year.

According to Deming, behaving in this way is management, not leadership. To create leadership in your organization, Deming proposes that:

- Leaders must know the work. How are you qualified to hire and train staff if you don’t understand the job?

- Leaders must remove barriers for hourly workers. Remove barriers to enable these workers to do their best. They are the drivers of your business.

- Leaders must work on sources of improvement.

Example:

Imagine you run a fashion retailer. Your hourly workers are those that work on the shop floor, helping customers. To remove barriers, you could create a feedback channel for these staff and quickly act on their suggestions.

8. Drive Out Fear

A culture of fear is not conducive to great work. Employees should not be scared of:

- Expressing a different opinion to the CEO.

- Ridicule.

- Relaying bad news or mistakes.

- Taking action on long-term goals, even if it means a hit to short-term goals.

Creating a fearless and blameless culture will increase product quality and employee retention.

Example:

You’ve just been put in charge of a team and, with it, inherited a culture of fear. Here are some actions you decide to take to eliminate this culture:

- Encourage views that differ from your own.

- Encourage people to provide bad news.

- When a team member makes a mistake, emphasize that the problem was caused not by them but by bad processes.

- Be approachable.

9. Break Down Barriers

This concerns breaking down the barriers between departments. Instead of just improving processes within each department, also focus on improving processes across departments.

Ways to achieve this include:

- Create internal customers by recognizing that each department has each other department as its customer.

- Build a shared vision.

- Use cross-functional teams.

Example:

Imagine you are CEO of a large company. You are concerned that your departments have conflicting goals, and communication and cooperation between departments is poor. To improve things, you consider:

- Creating a cross-functional task force to build out horizontal processes.

- Establishing internal customers and tasking each department to improve its quality to its internal customers continuously.

10. Eliminate Unclear Slogans

You have probably encountered slogans such as:

- “Take pride in what you do.”

- “Always go the extra mile.”

Deming says that you should get rid of these types of slogans as they can be detrimental to performance and quality. Why? Because quality is being held back by the system, not employees, and the system is the responsibility of management.

Instead of improving things, these slogans can lead to resentment and frustration in employees.

Example:

Imagine you are a manager wanting to boost morale and retention. You remove all slogans and instead decide to show employees what you are doing for them every month. This might include:

- Moving to a single suppler.

- Buying new equipment.

- Providing better training.

By showing your team that you are taking ongoing responsibility for allowing them to work smarter and not harder, you should begin to increase morale and retention.

11. Eliminate Management by Objective

This principle is similar to principle 7, Institute Leadership, and also controversial. Your aim should be to replace management by objective with leadership.

All too often, management sets numerical targets, frequently based on the average output of employees. This creates a twofold problem. Half your team won’t be able to hit the target, and the other half will find it too easy. Overall, this has the effect of reducing morale.

Improvement should come from not focusing on the result but instead on the details.

Deming is not advocating the abandonment of all measurement, but saying that you should move away from measuring employees’ performance relative to targets and focus instead on improving the quality of your products and processes. It is fine, however, to measure employee competency.

You then measure the capability of your people, not their output.

Example:

You are a manager and decide to get rid of management by objectives. Instead, you replace this with hands-on actions to increase the capability of your people: more training, continuous improvement, more communication about inputs, outputs, and processes.

12. Remove Barriers to Work Pride

Remove the barriers that stop your team from taking pride in their work. You can do this by switching your focus from volume to quality of output and process.

Build into your processes the ability for workers and management to improve the quality of the processes they use.

Example:

Imagine you have recently been appointed to lead a team manufacturing widgets. Morale is low because although the team are experts in what they do, they have no authority to change the processes that they perform.

You decide to help your team regain pride in their work by:

- Allowing them to stop production when they encounter a problem to fix the issue at source once and for all.

- Encouraging employees to raise concerns and responding quickly to those concerns.

13. Implement Education and Self-Improvement

Implement a vigorous program of training and self-improvement to improve the skills of all workers and managers.

Building your team’s skills will increase employee retention, make them better able to improve processes, and make them more adaptable to future change.

Example:

Imagine you’re a manager that has just taken control of a team where training has previously been performed on an ad-hoc basis.

You decide to improve this by:

- Creating a system that ensures ongoing training.

- Tracking and reviewing the training of each team member.

- Creating Personal Development Plans for each team member.

14. Make Transformation Everyone’s Job

The final point of Deming’s 14 Points is that transformation should be the job of everyone in the organization.

Although your team can’t produce quality better than the constraints the management system places on them, it is everyone’s job to work together to transform, not just managers.

Transformation is a journey that requires commitment and input from everyone. Only over hundreds or thousands of tiny improvements can you transform the whole organization.

Example:

Assuming you have a vision for where you want your organization to go, the perfect tool to transform an organization using hundreds of small steps is the PDCA Cycle.

As you can see, each iteration of the PDCA Cycle builds on the last to improve quality over time.

Advantages and Disadvantages

There are several advantages and disadvantages associated with Deming’s 14 Points.

Advantages

- You can pick and choose which of Deming’s 14 Points to implement, making it easy to get started.

- They encourage you to think about the benefits of committing to long-term quality improvement. These include reduced costs, more engaged employees, and happier customers.

Disadvantages

- Although Deming provided his 14 Points, he did not offer any guidance or tools to implement any of them. That is up to you.

- There is some overlap between many of the points.

Deming’s 14 Points Summary

Deming’s 14 Points are a set of management practices that help improve an organization’s products, services, and processes for the long term. They stem from the idea that quality improvement is driven by rooting out variation.

Ultimately Deming’s 14 Points aim to help you create a virtuous cycle of continuous quality improvement, resulting in decreasing costs, happier employees and customers, and increased profit.