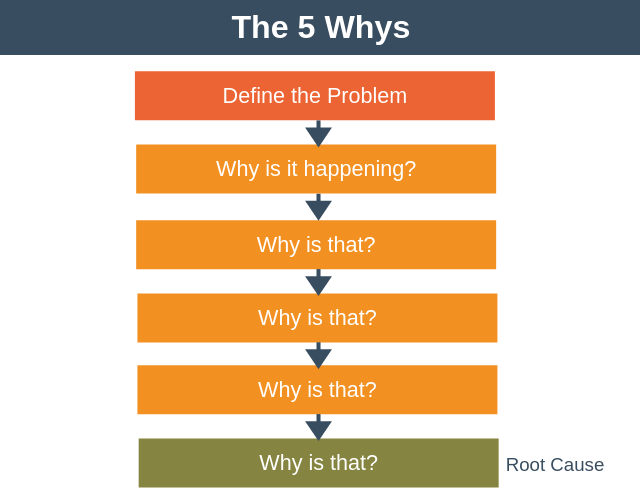

The 5 Whys is a technique that can help you to find the root cause of a problem.

It’s a fact of life and business that sometimes things go wrong. Software fails, equipment breaks, communication is misunderstood, and the master plan you’ve spent the last month putting together falls apart after five minutes.

To prevent these types of problems from reoccurring you usually need more than just a quick fix. The 5 Whys can be a useful tool in helping you to get to the root of what went wrong. By understanding the root cause of the problem, you can solve it in such a way that it doesn’t reoccur.

When something goes wrong, it can be tempting to leap into “crisis” mode, trying to immediately fix the issue and find someone on whom to pin the blame. A better way to react is to see the problem as a learning opportunity. Immediately after our initial fix is in place, the 5 Whys Technique can help us identify all the causes of the problem, so that we eliminate the problem for good.

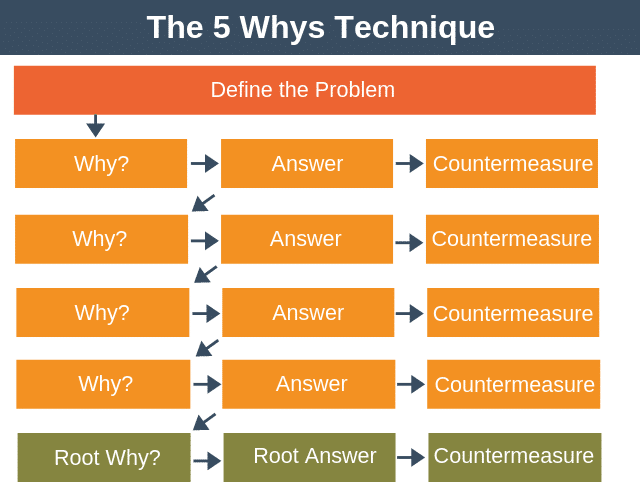

The technique works by asking why five times to find the root cause of your problem.

Background

The 5 Whys Technique was developed within the Toyota Motor Corporation in the 1930s.

Taiichi Ohno, one of the inventors of the technique, wrote in his book, Toyota Production System: Beyond Large-Scale Production, that “… by repeating why five times, the nature of the problem, as well as its solution, becomes clear.”

Today, the technique is in widespread use outside of Toyota and is used within Kaizen, lean manufacturing and Six Sigma. Eric Ries wrote extensively about the 5 Whys Technique in his book The Lean Startup (summary here), showing how startups can use the technique to solve their problems efficiently.

5 Whys Example

Suppose that your company’s website is down. You obviously need to get the site back up and running as a priority. Immediately after the site is back up and running you might then find it useful to use the 5 Whys technique to ensure that all the causes of the problem are addressed so that it doesn’t happen again.

Let’s take a look at what might have caused your website to go down.

- Problem: Website went down.

- Why did it happen? It ran out of memory.

- Why? Because it was incorrectly configured.

- Why? Because the site admin made a mistake.

- Why? Because development hadn’t provided adequate instructions.

- Why? Because they assumed it was obvious.

So far you might be thinking that this technique is so basic that it doesn’t require an entire article to explain it! Well, it’s the next step where the real power of the 5 Whys is revealed. You now need to take corrective action (called countermeasures in the model) at every level of the 5 Whys. For example:

- Cause 1: The website ran out of memory.

- Countermeasure: Get the site up and running again.

- Cause 2: Incorrect configuration.

- Countermeasure: Create a Standard Operating Procedure to verify configuration before every update.

- Cause 3: Site admin made a mistake.

- Countermeasure: Make sure site admin knows how to run the new verification test.

- Cause 4: Development hadn’t provided adequate instructions.

- Countermeasure: Train dev team to provide sufficient instructions.

- Cause 5: Assumed it was obvious.

- Countermeasure: Have a word with dev team manager to ensure they speak to their team about the importance of being precise no matter how obvious it seems.

The diagram above has been updated to reflect the entire 5 Whys process:

Over time as you fix problems in this way, you will build more robust processes and systems, resulting in fewer problems happening in the first place.

One thing to note from the example is that often what at first glance appears to be a technical problem transpires to be a human or process problem at its root.

What About Expensive Fixes?

You might be thinking that the example is all very well and good but what should we do in a situation where the solution is extremely expensive? The answer is that its all about being proportionate in your investment.

For example, suppose fixing the root of our problem is going to require migrating the entire system to a new platform, and that this is going to cost $150,000.

Well, if your website is crashing one per week and each time costing you $10,000, then it obviously makes financial sense to invest the money and fix the problem asap.

If however your website only crashes once every three months then you may choose not to fix the problem. In this way, the 5 Whys enables you to make the best decisions for your organization.

Rule of Thumb

Asking why five times is a rule of thumb. You may have to ask “Why?” just three times or even ten times to get to the real root cause of the issue you’re investigating.

How to Run a 5 Whys Meeting

To use the model follow these steps:

Step 1: Organize a 5 Whys Meeting

Organize for everyone who might be affected by the problem or have input to its solution to attend a 5 Whys Meeting.

If you are not leading the session then make sure that someone is. It is the session leaders responsibility to lead the 5 Whys process and assign people as being responsible for countermeasures.

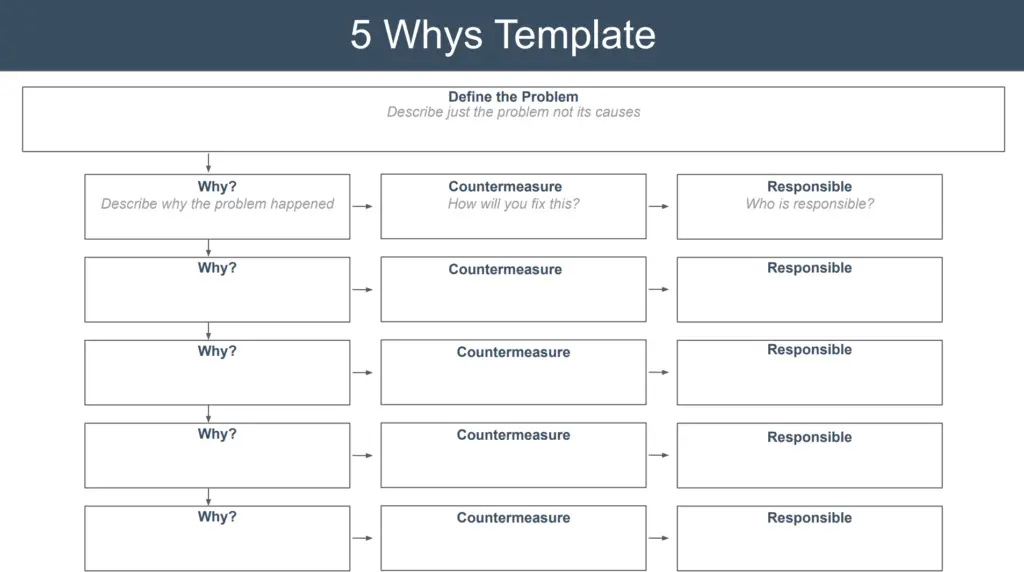

Step 2: Define the Problem Statement

At the start of the session, you should define the problem you are trying to solve. Write the problem on a whiteboard if you can.

It’s essential to keep the problem statement focused only on the problem. Do not state any possible reasons for the problem or make any assumptions.

Step 3: Ask the First “Why?”

Ask your assembled team why the problem is occurring.

Try to avoid entertaining answers that are guesses – stick to facts. If there is more than one reason given for the problem, then ask your team to vote on the most likely cause.

Write their answer next to the first why on your whiteboard.

Step 4: Ask “Why?” Four More Times

Ask why another four times, each time using the previous answer to base your question on. Once you have done this, you will have five reasons, one for each “why?” question.

As previously mentioned, you may need to ask why more times than five if you haven’t got to the root of the problem.

Step 5: Determine your Countermeasures

Agree what countermeasures you will take to address each of your five reasons that are now on the whiteboard.

Step 6: Assign Responsibilities

For each countermeasure, agree who is responsible for it and how they will measure the success of that countermeasure.

Step 7: Monitor Progress

Agree how progress will be monitored. Usually, this will involve a follow-up session in a few hours, days, or weeks.

During your follow-up meeting, you may need to adjust your countermeasures, or even create new ones, depending upon how successful the previously agreed countermeasures have been.

Step 8: Close the Meeting

Now that you have determined all the causes of your problem including the root cause, determined countermeasures, and how you will monitor progress, its time to bring your meeting to a close.

Advantages and Disadvantages

The advantages of the 5 Whys include that it:

- Allows you to identify the cause of your problem, not just its symptoms.

- Is simple and easy to use.

- Helps you avoid taking immediate action without considering if you’ve identified the real root cause of the problem.

- Helps you build a culture that embraces continuous improvement.

The disadvantages of the 5 Whys technique include:

- Different people may get different answers as to the cause of the same problem. This raises a question about the reliability of the technique.

- The method can only be as good as the knowledge and experience of the people using it.

- You may not dive deep enough to uncover the root cause of the problem entirely.

5 Whys Template

If you’d like to use the 5 Whys Technique for yourself and your team you can download our 5 Whys Template as a PDF document here.

Summary

To prevent some problem from recurring you need more than just a quick fix. The 5 Whys is a useful technique that can help you analyze and fix problems so they are eliminated for good.

The technique works by asking why five times. For each answer you discover, you deploy countermeasures to stop it happening again. Continue asking why until you have uncovered and addressed the root cause of the problem.